DIY Paint Protection Film: Risks Uncovered

DIY Paint Protection Film: Risks Uncovered

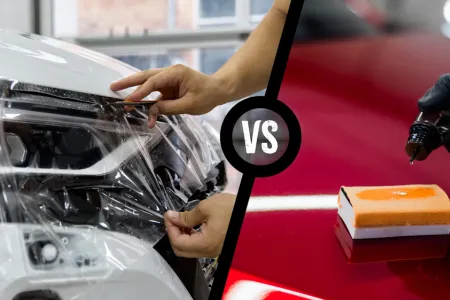

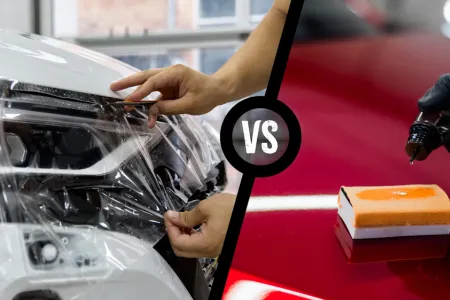

DIY vs Pro

What Comes in DIY PPF Kits

Most do-it-yourself paint protection film kits arrive with pre-cut polyurethane sheets, a squeegee, spray bottles for slip and tack solutions, and a hobby razor for trimming seams. Promotional videos make the process look easy, so many drivers expect to save money by skipping the shop. Doorstep delivery and glowing reviews praising “weekend installs” add to the appeal.

Reality differs: tools are basic, patterns cover mostly flat panels, and complex curves on bumpers or mirrors stay unguarded. Claims of self-healing layers and yellowing resistance overlook controlled humidity, filtered water, and practiced technique, leaving buyers with restocking fees or patchy, underperforming coverage.

Hidden Costs of DIY PPF

The biggest shock for first-time installers is how unforgiving paint protection film becomes once backing peels away. Adhesive grabs paint as moisture evaporates, so every second matters when aligning wide hood sheets or curvy bumpers. A slip-solution mixed even slightly wrong causes premature tack, locking in wrinkles and dust that balloon into cloudy blisters. Re-lifting stretches the film, weakening its self-healing topcoat. Edges trimmed without heat soon lift, trapping grime and leaving a dirty outline.

Even when the film lies flat, durability depends on meticulous prep. Skipping paint correction leaves swirls visible beneath clear polyurethane. Garage temperature swings create bubbles, and dull blades carve ragged seams that invite water. Static-cling strips fare worse, peeling after one power-wash. Replacement sections rarely match aged film, leaving patchwork gloss.Factor hours lost and the budget quickly eclipses a professional paint protection film service completed by experts.

Professional Installation Advantages

Certified installers use software plotters to cut patterns precise to your trim, eliminating risky blades on paint. They machine-polish away swirls, then apply film in a climate-controlled bay with calibrated slip solution. Heat guns seal edges so nothing lifts at highway speed. Self-healing topcoats erase light scratches, color stays crystal-clear for five years or more, and every job ends with warranty registration and a clear bra installation process walkthrough—debunking the common myths about paint protection film once and for all.

Certified installers use software plotters to cut patterns precise to your trim, eliminating risky blades on paint. They machine-polish away swirls, then apply film in a climate-controlled bay with calibrated slip solution. Heat guns seal edges so nothing lifts at highway speed. Self-healing topcoats erase light scratches, color stays crystal-clear for five years or more, and every job ends with warranty registration and a clear bra installation process walkthrough—debunking the common myths about paint protection film once and for all.

Cost objections fade once long-term factors enter the math. Shop-grade film guards high-impact zones from chips that would require expensive repainting. Documented PPF boosts trade-in offers and passes lease inspections with no deductions. Insurance adjusters often accept photos from a professional install when processing claim repairs, adding another layer of value.

Opting for professional paint-protection film installation brings genuine peace of mind. Registered batch numbers link each roll of film to the vehicle, so warranty claims or replacement panels are handled swiftly through the manufacturer rather than a generic customer-service line. Labor is guaranteed, covering edge lift, bubbles, or discoloration that might appear years later. Technicians heat-seal seams and apply edge primer, enabling the finished wrap to endure automatic car washes, high-pressure rinses, and corrosive winter road salt. Those durability assurances, plus documented proof of workmanship, simply aren’t available with a driveway do-it-yourself kit

Real Costs of DIY Failure

DIY kits tempt buyers with low prices, yet hidden fees pile up fast. Separate sprayers, lint-free towels, edge primer, and a heat gun rarely come in the box. Misalign one bumper piece and rush-shipping a replacement sheet wipes out savings. Multiply that risk across hood, mirrors, and rocker panels, and material alone can match a shop quote. Add weekend hours spent studying videos and trimming jagged edges, and the bargain vanishes.

The price of errors grows later. Uneven squeegee pressure can scar clear coat, overstretching thins self-healing layers, and trapped moisture oxidizes into white rings. Dealers flag poor film during trade-ins, deducting value for removal and repaint. What began as a money saver ends up a resale penalty.

PPF Kit Lifespan vs Pro Films

Professional-grade films use elastomeric polymers that self-heal under heat, maintaining clarity for up to ten years on Texas roads and carrying warranties against yellowing. DIY kits rely on thinner consumer formulations; many haze or peel after three summers, especially on sun-blasted hoods.

Professional-grade films use elastomeric polymers that self-heal under heat, maintaining clarity for up to ten years on Texas roads and carrying warranties against yellowing. DIY kits rely on thinner consumer formulations; many haze or peel after three summers, especially on sun-blasted hoods.

Heat cycling accelerates adhesive fatigue. Shop installs receive edge sealing, infrared curing, and use different grades of paint protection film for maximum bond. Garage jobs cure unevenly; cold nights shrink film before adhesion finishes, leaving micro gaps for grit. Months later, stained borders appear, and peeling panels cost more than a pro job ever would.

Professional maintenance stretches a clear bra’s service life well beyond its baseline warranty. At an annual visit, technicians steam-clean edge seams, draw out hidden grit, lay fresh edge sealant, and restore the topcoat’s slick feel using manufacturer-approved cleaners that never cloud the film. They also inspect high-impact panels for lift or deep chips and replace a single section under warranty if needed. DIY owners rarely schedule this level of care and often reach for harsh degreasers or abrasive pads that strip hydrophobic layers, accelerate yellowing, and void any coverage.

Why Pros Add Real Value

Value is more than purchase price—it’s the lifetime cost of keeping paint pristine. A pro clear bra shields bumpers from rock chips that average $1,500 per repaint, preserves factory texture, and enhances buyer confidence. Transferable warranties and digital records follow the vehicle, and fleet managers rely on standardized labor rates and rapid panel swaps. High-output LED lighting detects debris, optional ceramic topcoats add slickness, and a written warranty covering lift and discoloration can save thousands if gravel strikes a fender.

Choosing the Right Protection

Before deciding, add every expense: tools, extra film, heaters, slip-solution refills, cleaners, and the weekend hours you could spend elsewhere. Only shop film offers thicker, stain-resistant layers or stealth matte finishes that match factory paint. Garage dust guarantees debris under film, and keeping a vehicle beyond the loan payoff means original paint matters for resale. For most owners, professional work delivers a stronger return on investment and far less stress.

When collecting quotes, look beyond sticker price alone. Inspect bay cleanliness, certifications, humidity controls, and view sample film edges. Ask about pattern libraries, edge primers, infrared curing, photo documentation, and warranty repair policies. Confirm turnaround times, loaner options, and ongoing maintenance costs. Balanced decisions weigh these factors against DIY uncertainty, revealing that expert installation, consistent quality checks, and transferable warranties create protection that truly lasts and supports future resale value.

Final Verdict on DIY PPF

After weighing costs and risks, most owners learn DIY kits suit only hobbyists willing to accept flaws. Professional installation converts risk into long-term value: self-healing coverage, rock-chip defense, and solid resale gains—all backed by warranty. Combine that security with time saved and higher trade-in offers, and the premium over a kit is quickly recovered.

Tempted by a kit? Wrap a spare mirror cap as a test. Track wasted film, hours invested, and final quality, then compare with a shop demonstration. Pros use calibrated solutions, controlled bays, and pattern-specific skill that no instruction sheet can match. The side-by-side difference proves real protection comes from expertise, not a cardboard box.

Get our latest news and promos

SATISFACTION GUARANTEED

UNPARALLELED SUPPORT

Sun Shield of Lubbock

Social Media

Payments Accepted